Silvagrip's innovative all-metal construction isn't just theory – it's proven in the most demanding real-world applications.

US Navy & Government Approved: Silvagrip is a Qualified Product List (QPL) approved non-skid material, meeting the rigorous standards of MIL PRF 24667-XI. This official military specification approval underscores its exceptional durability and reliability. Furthermore, Silvagrip products are available for government and military procurement via specific National Stock Numbers (NSNs), a testament to its trusted status within federal operations.

Tested in Extreme Conditions: The advanced material used in Silvagrip is the same technology deployed and tested on the flight deck of the USS Wasp for F35B vertical landing operations. If it can withstand the intense heat and forces generated by modern jet aircraft, it's ready for your toughest challenges.

Industry Recognition: Silvagrip has been featured in leading industry publications such as Offshore Technology and The Maritime Executive for its groundbreaking design and superior performance in marine and industrial environments. It's recognized as a long-lasting, cost-effective alternative to traditional anti-slip coatings.

US Navy published new nonskid Military Specifications in Dec 2022. Silvagrip has qualified to meet class C now as well. Silva Non Skid Solutions w/Silvagrip has been awared the QPL status of all 3 Applications of A, B and C

MIL SPEC - DECK COVERING MATERIALS, TILE AND SHEET FLOORING (DEC 2022)

Bollinger Shipyards is currently building three new government research vessels that will have Silvagrip® installed on them.

Silvagrip® signs NDA with one of the world’s largest ship builder.

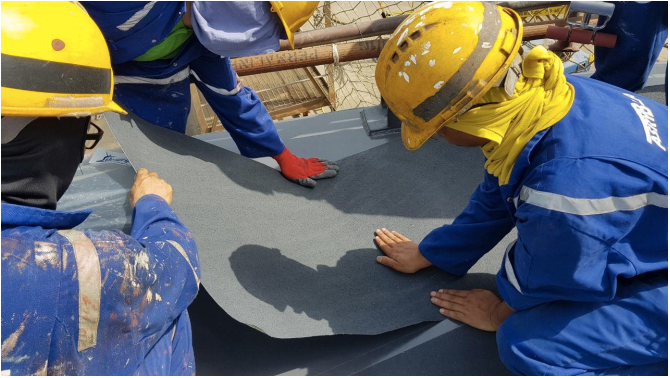

USS Firebolt Installation Begins

Laying the Silvagrip® down carefully.

Sealing the edges of Silvagrip® with Silva seal.

Both samples had just over one half of a percent material loss.